Sourcing and Procurement

Every business has the basic need to acquire goods and services to run the operations. It is an ongoing process and requires targeting the correct suppliers and buying the required products or services. Although it sounds very simple, this cycle needs to be handled strategically to get maximum returns.

Should companies engage in unstructured buying? Or purchase goods just for economic gains without being socially and environmentally conscious? As globalization and advancement in technology come into the picture, all companies will eventually have to adopt best practices and a structured approach for sourcing and procurement.

Several people confuse procurement with purchase, and sourcing with outsourcing, etc. Today we take an in-depth dive into the core business components; “sourcing and procurement,” and how they contribute to your business growth.

Sourcing and Procurement for Business

The art of identifying the correct suppliers and negotiating for a lower price before finalizing the contract is worth learning. It enables companies to transform from good to great in growth as well as profit maximization.

This article will provide you a breakdown of the following;

- What are sourcing and procurement

- The process of sourcing and procurement

- Types of sourcing and procurement

- Why are these considered as the backbone of any business

- How to effectively use sourcing and procurement for achieving better results.

Sourcing

Sourcing is a critical activity of choosing the vendor, which includes analyzing what needs to be purchased, why it is required when to acquire it, and from where.

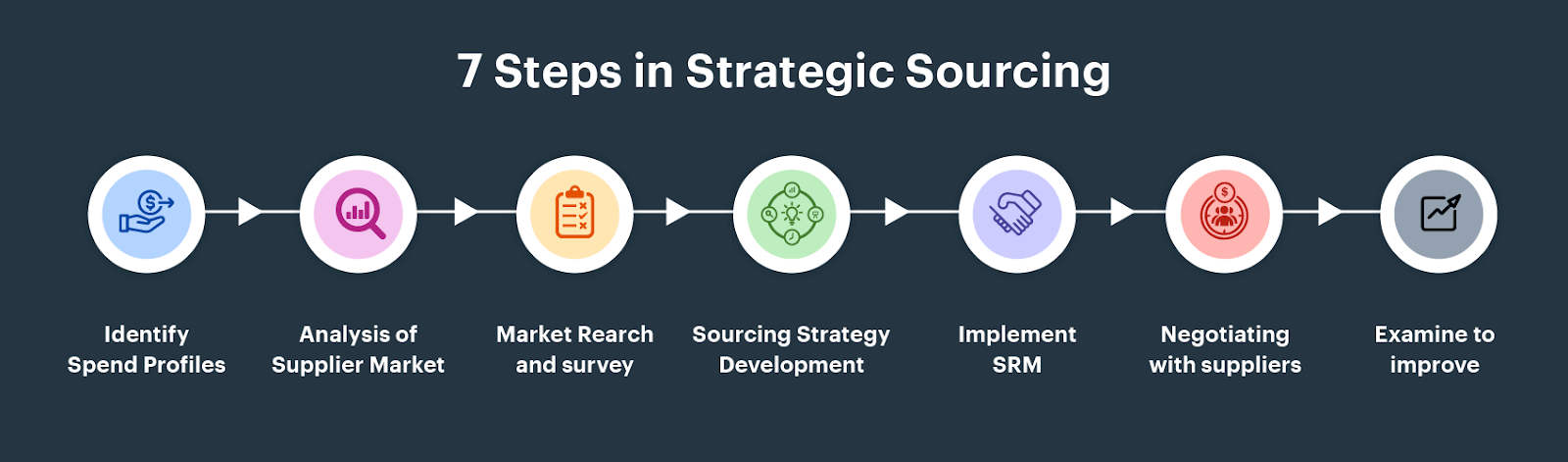

The 7-Step Sourcing Process

1. Analyze; Identify Spend Profile

Knowing your business needs is the first step to deciding which supplier to choose. The analyzing stage includes deciding on;

Category or Commodity Type: The type of goods or services such as raw materials or finished products is based on your industry.

Quantity Required: Once the product is finalized, the quantity required needs to be assessed.

Budgets: Know your budgets in line with the category you are going to enter.

2. Analysis of Supplier Market

Vendors Strength: It is important to analyze the industry intensity; for example, if the vendor is a sole supplier for a particular commodity or service, he would have greater intensity. On the other hand, if there are many suppliers in the market, the hold of one entity will be less.

Bargaining Power: If the supplier’s goods are critical for your business, they would have the upper hand on the deal.

Supplier Swapping: The market should have more than one supplier options to choose from or switch to. But, unfortunately, this makes the suppliers vulnerable and resists a long-term relationship.

Industry Situation: If the industry is not expanding, the suppliers will become weaker due to an increase in competition.

Ease of Entry: A hassle-free and easy entry into a particular type of industry can hike up competition amongst suppliers making their position weaker.

Company Size: If your company size ratio is the same as many others, the suppliers will take the lead.

3. Market Research and Survey

The strategy should be aligned with the business goals and designed, keeping in view the following criteria.

Supplier Characteristics and the number of suppliers in the market, Location, Quality of Product or Service, Ease of Communication, Customer Service Level, Payment policy, Methods of Delivery, Supplier’s Production Process, Reputation, Environment friendly, Culture of the organization.

4. Sourcing Strategy Development

Where it is important to go with a supplier who can provide quality products promptly, there are a several factors that you need to keep in consideration while devising a sourcing strategy. This phase includes summarizing and analyzing all the data extracted previously through research.

5. Implement CRM

Before negotiating, we need to do our opportunity analysis and develop forecasts, then only derive recommendations to close a deal in our favor.

6. Negotiating with Suppliers

This step requires negotiating over terms, conditions, or service level agreement; building a lasting relationship with the supplier, especially if the commodity or service is integral for the business. At this stage, the requirement should be jotted down, and a clear picture should be provided to the supplier about what matters to your business.

7. Examine to Improve

Governance is the key factor when it comes to monitoring the supplier’s performance. It enables the company and the supplier to be on the same page and cooperate.

Procurement

The process of obtaining or buying supplies from an external source is called procurement. It is carried out on a large scale and involves both a seller and a buyer. But here, we will focus on the buying side of the activity to develop a thorough understanding of procurement.

Procurement can be traced back to when trade/commerce was introduced. Then, it was limited to a buying or purchasing activity with manual receipts and records. However, the emerging technology trends have evolved the procurement process as fundamental for any business that includes selecting reliable suppliers and getting fair prices. This results in higher ROIs and profitability if carried out diligently.

Types of Procurement

- Direct Procurement

- Indirect Procurement

- Goods Procurement

- Service Procurement

Direct Procurement

This type of procurement is done for manufacturing purposes and involves raw materials, machinery, or items purchased for resale. It is vital for any business, as the materials procured will contribute to its final product.

It requires collaboration between buying party and the suppliers, as it is an ongoing process.

Indirect Procurement

The purchase of consumables or perishables is required for a company’s day-to-day operations, specifically for internal use. These include office supplies, utilities, and travel.

This can be executed with a transaction-based short-term relationship with the supplier.

Goods Procurement

This procurement is basically for inventory purposes of both the Direct and Indirect Procurement, like wholesale items and office supplies also raw materials.

Services Procurement

Arranging a workforce or providing consultancy. It also comes in handy for software subscriptions used by businesses. This activity is carried out for people-based services like security, law firms, and labor.

The relationship with the supplier is just contractual.

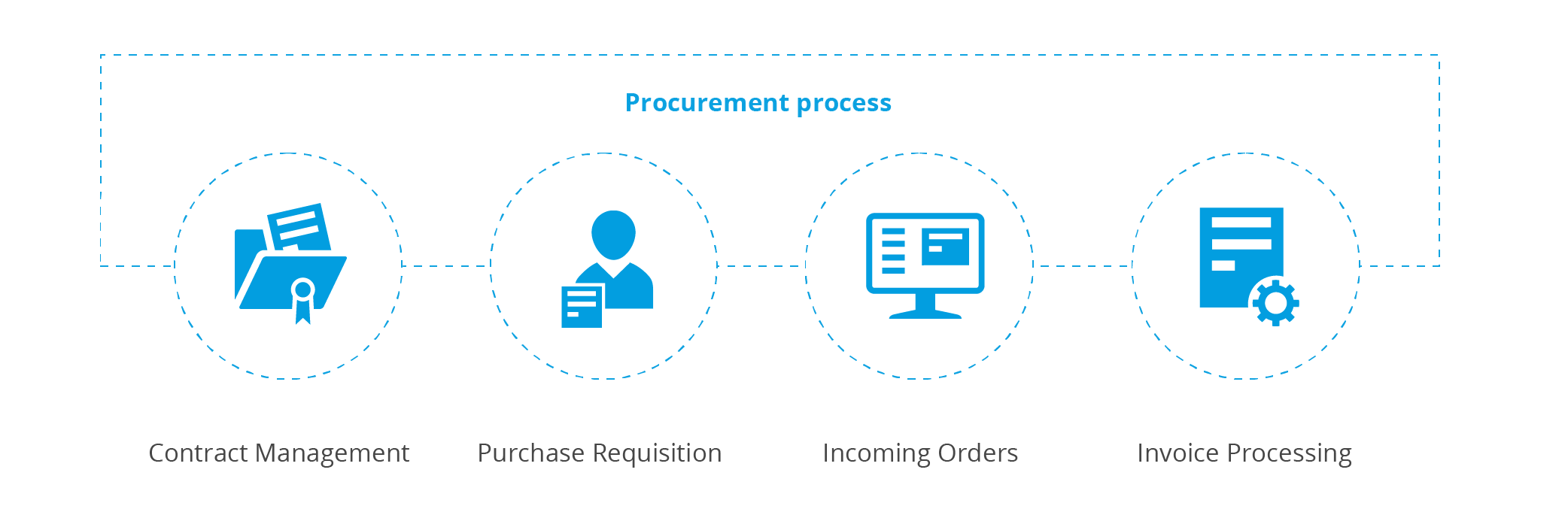

Procurement Process

A company needs a process, specifically a procurement process, to follow certain steps to achieve the organizational objectives. The process flow may vary depending on the industry it is being created for. But the basic purpose remains the same as boosting efficiency and maximizing value for the business.

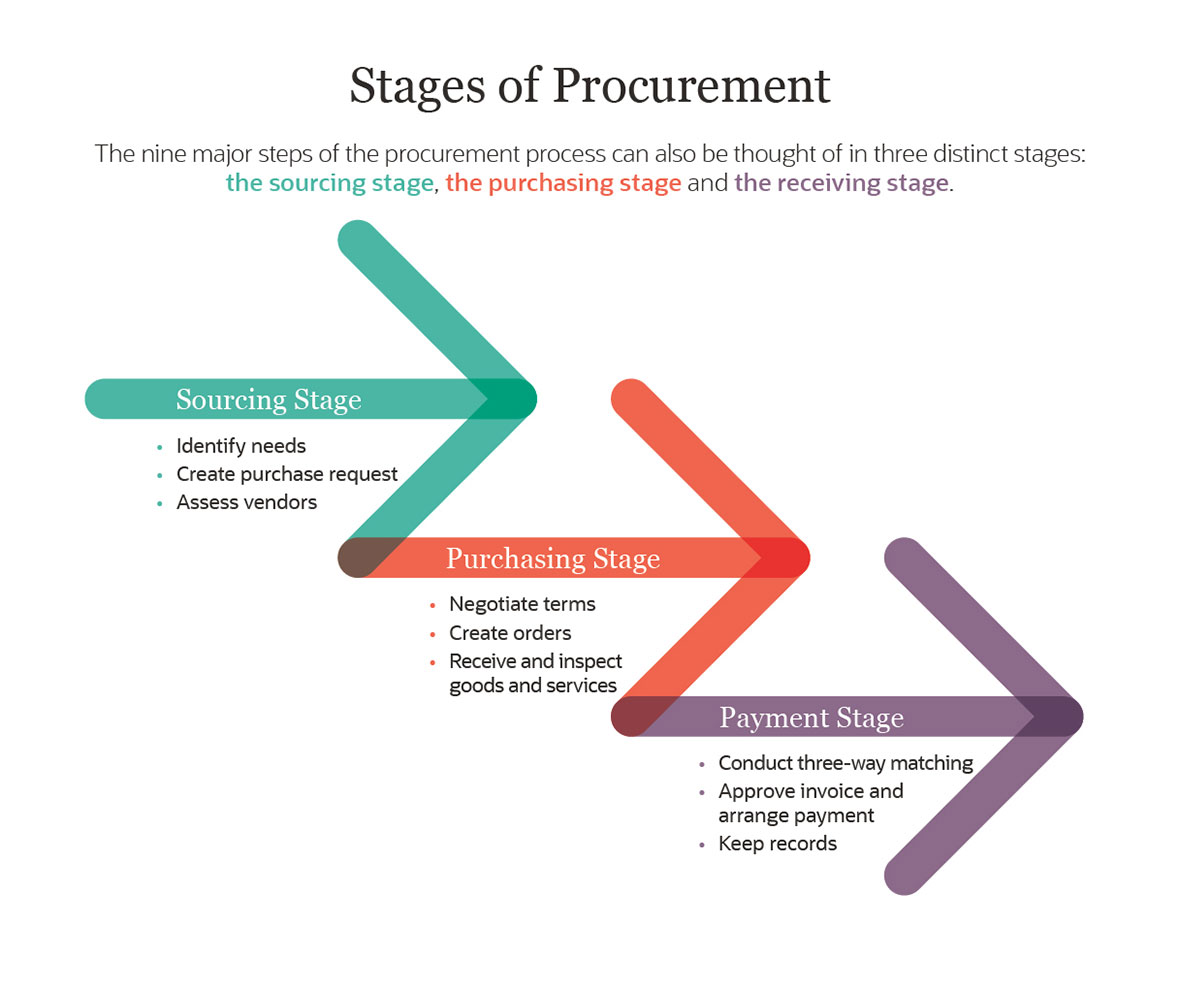

There are 3-stages in the procurement process that can be further segregated to form 9-steps to understand the procurement concept better.

- Sourcing Stage

- Purchasing Stage

- Payment Stage

The Sourcing Stage

- Requirement Identification and Specifications

Businesses need to regularly obtain items, some of which can be new products, or re-stock some previously procured items. Also, a detailed specification needs to be created for the potential supplier. It can be technical specifications about the goods or defining service characteristics. All departments are involved before proceeding further.

- Purchase Requisition

To make a bulk purchase, certain levels of approval are required. First, a purchase requisition is created, including the quantity required, the time frame the product or service is expected to reach the business, and the quoted price. It is at the discretion of the purchasing department after consultation with the stakeholders to either approve or reject the requisition. In case of approval, the procurement team contacts the selected vendor for the purchase.

- Vendor Selection

This step can be referred to as sourcing as well. It is the stage where a thorough investigation is required about the supplier before extending the business relations. It all depends on the emerging needs of the business to work with new suppliers or rely on existing suppliers. All the sourcing factors discussed in this article need to be considered before finalizing a potential supplier.

The Purchasing Stage

- Negotiate Terms and Conditions

Now comes the time to discuss the price factor; it is advisable to get at least 3 quotations before deciding. But other factors such as reliability, quality, and ability to provide timely solutions should be given some thought. A bidding process can be used for transparency. Having more than one supplier takes away the negotiation power from the buyer, whereas working with a particular supplier can give an edge or more bargaining power.

- Creating a Purchase Order

A purchase order (PO) is generated after the 4 stages mentioned above are executed. It has all the specifications of the commodity or service as well as the finalized price quotation.

- Delivery and Inspection

Once the goods are received, a thorough inspection for any damages or failure to fulfill the agreed specifications should be carried out.

The Payment Stage

- Three-Way Matching

To ensure no discrepancy in the invoices, the accounts department will match 3 documents: the purchase order, the order receipt, and the invoice. The payment process is initiated only after clarifying doubts in all documents.

- Arranging Payment

Timely payment processing helps evade late fees and can lead to a stronger bond with the suppliers. Both parties can mutually agree upon the mode of payment.

- Record Keeping

It is mandatory not only for audit purposes but also to re-order from the same supplier and avoid unnecessary disputes.

Current Practices of Sourcing and Procurement

Responsible Sourcing

This is a relatively new term introduced to keep the environment and society as the top priorities rather than the business and economic needs. It instigates a positive yet critical thinning when choosing the suppliers to evade any form of labor exploitation, environmental damage, or bad practices.

It creates a social consciousness and ethics in the sourcing process to build connections that do not affect the environmental and societal norms. In addition, everyone has access to social media in today’s era, so companies need to be more conscious about their image than ever before. Thus following ethical sourcing is not an option; it is the need of the hour.

Example of Ethical Sourcing

Businesses like Patagonia, H&M, Starbucks, and The Dr. Pepper Snapple Group have risen to the occasion and set a benchmark for others to follow.

Now let’s look into how Starbucks shined out in the market. It uses C.A.F.E (Coffee and Farmer Equity Practice) to ensure social responsibility, quality, economic transparency, and environmental leadership. It ensures that from plantation till the purchasing, each step is done ethically.

Strategic Sourcing

This type of sourcing creates a synergy between the company and its suppliers by introducing a cyclical process. As a result, it helps in building a long-term relationship and hence maximizes value.

The distinguishing feature of strategic sourcing from normal sourcing is that it is an entire process that includes the supply and the service, quality, and continuous innovation. Unlike sourcing, the focus of which is just on pricing.

Example of Strategic Sourcing

The store 7 Eleven is the ideal example when it comes to Strategic Sourcing. It let go of its vertically integrated strategy and started utilizing its suppliers to carry on its day-to-day activities resulting in reduced costs and higher returns. This also shows the synonymy between sourcing and outsourcing.

Like they say, “Don’t keep all the eggs in the same bucket.” So 7 Eleven started leveraging and relying on suppliers’ capabilities to become a market leader in the superstore industry.

E-Procurement

As businesses realize that procurement is a vital element affecting profitability, they have started investing in new tools for procurement. Now we hear about procurement software that helps in market analysis and assist in making planned decisions.

Tips and Tricks for Better Sourcing and Procurement

- Maintain the highest standards of social responsibility and work with ethical suppliers.

- Switch to software to cut down the research time and make quick and informed decisions.

- Constantly refine the procurement process by involving all stakeholders.

- Always follow the hierarchy for making decisions.

- Try to build lasting relationships with the vendors.

- Look at other aspects like quality and timely delivery while choosing a supplier and not always focus on a lower price.

- Dispute management is critical for building trust between both parties.

- Cost management can only be achieved by proper inventory management.

Conclusion

Sourcing and procurement are the keys to unlocking opportunities, working efficiently, achieving organizational objectives and enjoying lower costs, maximizing returns, and having strong collaborative relations with suppliers for the way forward.

CATEGORY

1 on 1 Dedicated Managers

for Personalized Solutions as your very own dedicated in-house team

CUSTOMER CENTRIC

success for our customers at the heart of every action

Transparent & Trusted

clear cut processes trusted by 2000+ global sellers & brands

Amazon Seller Solutions Providers

servicing Amazon’s Global Sellers across Global Marketplaces