The chaos caused by the covid-19 pandemic has left the world and its economy in a deplorable state. The repercussions that followed the lockdown during 2020 have disrupted all types and sizes of businesses. The post-pandemic norms and trends have molded the traditional supply chain and logistics into a new shape. The evolution of technology and modern consumer needs has brought dramatic changes in the procurement process as well.

The tech-savvy advances in the corporate world have led to an increase in the expectations of the millennials – the modern-day, or it would be better to call them the next-generation customers. The same-day delivery, flash sales, online deals have increased the demand and encapsulated the businesses with intense pressure.

The intensity of “consumer demand” has led to the evolution of the traditional supply chain into the modern supply chain. This evolution has navigated a need to blend into emerging trends from locally active management to a global expansion and intermingling in the international e-marketplace.

The modern-day supply chain has given birth to a more globally connected network for procurement and sourcing. Even the local businesses are now making an avid presence on the international platforms. Moreover, the gradual paradigm of technology has helped businesses and commerce to integrate different sources and curate a uniform flow of data and information that allows a hassle-free supply chain cycle.

As fascinating as it sounds, adopting the modern-day supply chain trends and taking a step forward to improvise the procurement cycle, businesses have to undergo major changes with up-gradation to Avant grande technological system. Moreover, it is crucial to deal with the two; procurement and supply chain- separately, as mixing them up can damage the profitable outcomes.

Understanding the Difference between Modern Day Supply Chain and Procurement

When you are dealing with trade and retail, buzz words like purchase, procurement, logistics, product acquisition often pop up. Even though the procurement process and the supply chain management are poles apart, they can be easily mixed up. Therefore, it is crucial to paint a distinct picture for the two.

Procurement

(The process of procurement has already been discussed in the previous article. Therefore, we will now only have a quick recap for it)

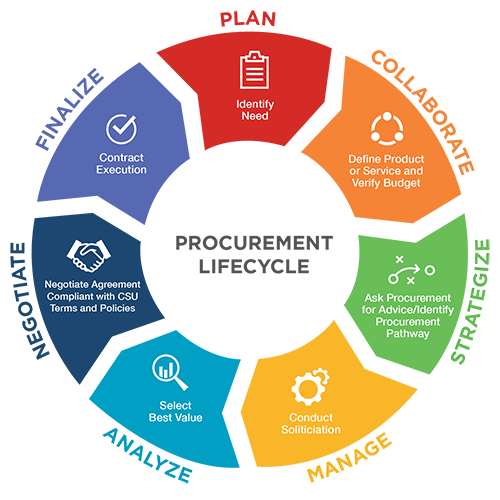

The procurement field deals with discovering, purchasing, and acquiring the supplies (products or services) as per an organization’s need or a particular department in the organization. From sourcing the supplies to signing contracts, hunting down the suppliers, managing and tracking the supplies to billing and other legal documentations, procurement covers it all.

When you compare it with sourcing and supply chain, the concepts might start to tangle in your brain. Think of procurement as an end-end process; it starts when the organization lists down the required supplies to the time the delivery is completed. It comprises of various branches such as:

- Sourcing for the suppliers and the supplies

- Estimating the market demand

- Inspecting quality and acquiring technical specifications

- Dealing with the vendors and negotiating the costs

- Management of the contract and other legalities

- Ensuring the timely delivery of goods and services

To learn more about sourcing and procurement, you can check out our previous articles.

You must be wondering that if procurement covers the entire process, what comes under the supply chain management. There is a lot more to the management of goods and services than you perceive.

Supply Chain Management

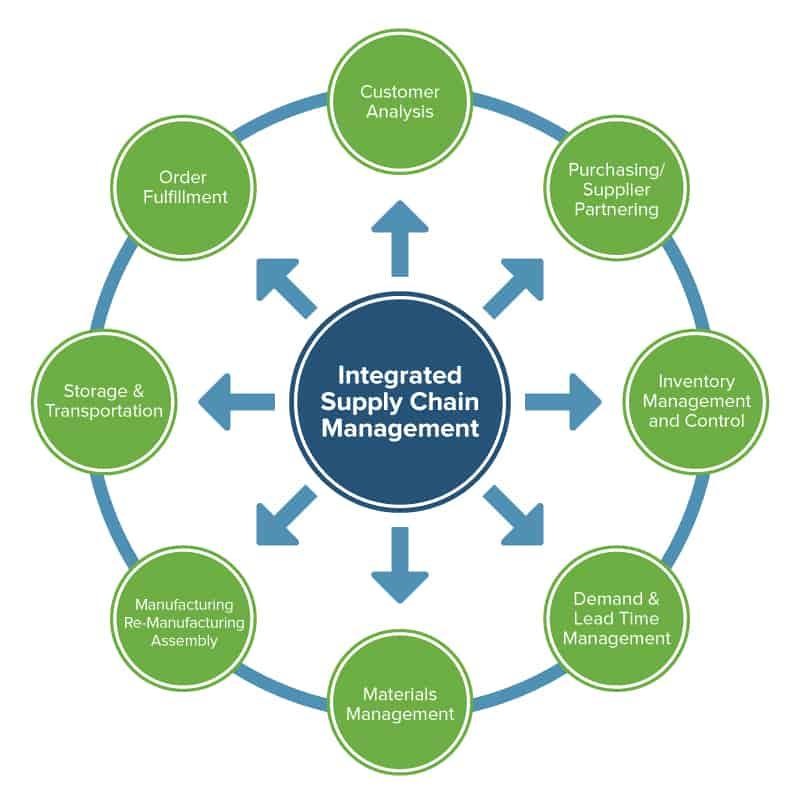

A supply chain is the entire network of manufacturers, vendors, logistics operators, and a team who work in coherence to turn raw materials into manufactured goods and ensure the product reaches the client. So now the question arises that what is supply chain management?

The supply chain cycle looks after quality determination, product marketing, procurement process, and sourcing.

Whereas supply chain management ensures the handling and functioning of the supply chain cycle. A hassle-free supply chain management is crucial to the company’s success and profitability. An effective supply chain strategy can:

- Increase profitability margins

- Generating annual revenue

- Helps the organization to surpass the market competition

- Looks after customer satisfaction

- Optimize supply chain cycle

- Helps to negotiate and reduce the costs for the organization

Traditional VS Modern Day Supply Chain- Understanding the transformation

The novel coronavirus, global trade war, changes in consumer demand that followed the global lockdown in 2020 have made the traditional supply chain management strategies vulnerable for every business worldwide. The corona-led consequences have navigated the need for a modern-day supply chain, pushing the traditional strategies and mode of product acquirement out of the picture.

The supply chain managers are struggling not to let their organization collapse under immense pressure. However, the transformation into the modern-day supply chain, the fast pivot to growth, has also created many challenges.

Traditional or modern-day, the three entities that are crucial to a functioning and profitable supply chain management are:

- Supplier or Vendor: the supply chain managers will have to hunt down the suppliers that can provide raw goods, products, services, energy, and components to the producer or manufacturer

- Producer or Manufacturer: they are the ones who turn in the raw materials into finished products

- Consumer: The person on which the supply chain ends in the customer who purchases the final finished product after it is successfully delivered to them

The best way to understand these entities is to consider the branded clothes that you (the customer) shop from the stores or online. The raw material (supplier) would be the fabric, and the manufactured product (producer) would be the clothes. Therefore, one cannot function without the other.

The Paradigm of Modern Supply Chain Management from Traditional Ways

This generation and the next are much more aware of their needs than our parents were already feeling too old, right?. However, since the beginning of this world, as humans evolved, so did the things around them. You would remember waiting for years and years to get your family or friend to bring you something from abroad. Or having to travel miles to trade your goods.

Now, when advanced technology is at your disposal, people just make things happen via a “click”. Therefore, the future is dark if any organization’s supply chain management has not made itself available for that “click” and still living the traditional strategies, the future is dark.

Here is a sneak peek into why the traditional ways are passé, and the modern-day supply chain is accommodating into:

1. Transformation of traditional supply chain management (SCM):

Supply chain management became an integral part of every small-scale business to a large organization in the 20th century. The business owners and entrepreneurs deciphered the efficient networking) locally and globally) navigated by the SCM. The era of SCM made it possible for even the perishable goods to be contained and delivered as good as new, such as some food products.

Over the years, supply chain management evolved with technology and adapted to worldly needs and norms. Common to everyone’s knowledge, SCM has modernized 100 times more in the year of a pandemic than in the last decade. From initiation to integration to the globalization and digitization era, supply chain management has seen the biggest modern-day paradigm.

The phases of supply chain management are:

- Phase 1- initiation, Globalization and specialization era (Traditional)

- Phase 2- Specialization and digitization era

- Phase 3- The current modern-day era (or, as the millennials would like to call it, SCM 2.0)

The current era of SCM 2.0 involves the use of digitization, automation, and Artificial Intelligence (AI). Most sourcing, procurement, freight forwarding, and logistics organizations are now a part of modern-day supply chain management.

2. Traditional Supply Chain Management:

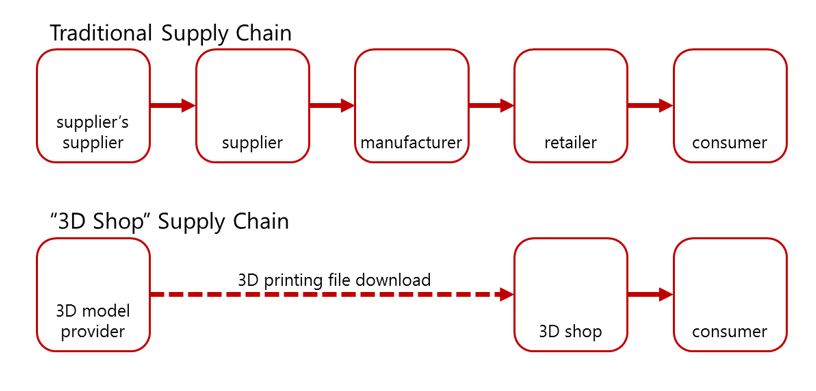

The traditional or initial day supply chain management involved simple strategies that were written down in journals and notebooks for a clear operational procedure such as:

- Acquiring the raw materials

- Collecting the materials from the vendors or the suppliers

- Manufacturing of the finished goods

- Distribution of the goods to the consumers

- Consumption and feedback by the customers

Traditional SCM is devoid of automation; hence the process, no matter how simple, takes a lot of time and effort no matter how simple. The evolution of technology has replaced conventional supply chain management with modern and more realistic strategies.

3. The Key Differences between Traditional and Modern Day SCM:

Here are the key differences between both:

- The traditional methods only focused on the production and supplying the goods. Nowadays, the modern-day SCM targets consumer demands. Technology and social media have made it possible for organizations to attain customer feedback and reviews and improvise accordingly. Moreover, the online platforms allow the customers to pitch in their demands and customize their products. The companies such as freight forwarders strive to provide timely and safe delivery instead of just focusing on product distribution.

- In the traditional SCM days, maintaining a partnership, handling overseas clients, or expanding the business in the international marketplace was next to impossible. There were no resources to maintain the global network. The modern-day SCM allows the organizations to reap the benefits of global e-marketplace, create a partnership, deliver the better value of their services and maximize ROIs.

- The modern-day organizations adapting to the newer ideation of SCM build strategies and online presence to land potential customers and provide high-end products or services to them. Whereas, the companies that still operate under the traditional SCM methods have no way to improvise the product value as per consumer demand.

- Traditional SCM has to operate manually. Even for listing the requirement of the raw materials to the quality of the finished products, the supply chain team has to manufacture and print the content book- supplying it to the manufacture is another tiresome process. However, the modern-day SCM utilizes the technology, created and publishes e-books, and just emails them to the relevant people. A classic example of saving money, time, and effort with better results.

- Modern SCM is more inclined toward creating international (or even local) partnerships, focuses, and collaborations. This allows a seamless online or physical trade with access to more suppliers and better manufacturers.

Summing it up, modern-day SCM tools and automation has enabled organizations to maximize their profitability, maintain a long-term client relationship and expand seamlessly into the international e-marketplace.

Proactive Methods for a Lucrative Modern Supply Chain Management (SCM)

Now that we are aware of the positive aspects of modernization and digitization, it is essential to evaluate the proactive methods that ensure mitigate the vulnerabilities for the supply chain cycle:

- Acknowledge the modern-day supply chain risks

Adapting to the technological paradigm calls for fail-proof SCM strategies that can negate the technological failures or manage the risks. Disruption risks are higher when the suppliers rely on the manufacturers and come back to the supply chain managers. It is crucial to integrate a synchronized and coherent supply chain team to eliminate the risk.

- Make the supply chain resilient

To strengthen the modern-day supply chain and mitigate the negative impact of a global crisis like the recent corona pandemic, the supply chain managers have to cater to more efficient sourcing, procurement, and freight forwarding process. Moreover, it is important to adapt to seek diversity, as they say, never put all your eggs in one basket.

- Stay open to improvisations and growth opportunities

The tech-savvy strategies call for flexibility and adaptability to the ever-fluctuating market pandemic- as proven by the global pandemic. Adapting to modern solutions like Lean Methods and automation can help alleviate many problems for continuous improvement and acclimate the post-pandemic economic landscape.

- Adapt to technological advancements

Modern-day problems require modern and technological solutions. Spurred by the pandemic and new kind of consumer and market demand, the modern-day SCM cannot lag behind in technological innovations. Nowadays, organizations need to incorporate advanced technology like blockchains, artificial intelligence (AI), automation, and geographic intelligence to form a digitally effective and connected modern-day supply chain management.

“In the millennial era-, do as the millennials do”

The Covid19 pandemic and the global economic crisis have made the world realize the importance of modernization. Modern-day supply chain management should acclimate and thrive on the traditional supply chain methods. The global shutdown has proven that some traditional ways, such as the off-shelf purchase can never be overlooked.

Therefore, the digital supply chain management has to align its goal and recruit third-party logistics operators, procurers, source, and freight forwarders to guarantee an effective supply chain loop.

In conclusion, improvement and modernization have to be synchronized to ensure a seamless customer experience and maximize profitability. Modern-day supply chain and procurement can land your business in the international e-marketplace while giving the organization the power to monitor every move and track the supplies and their deliveries without being physically present.

To insulate your organization from any unforeseen circumstances or the next global crisis, modern supply chain management with automated strategies is the need of time.

CATEGORY

1 on 1 Dedicated Managers

for Personalized Solutions as your very own dedicated in-house team

CUSTOMER CENTRIC

success for our customers at the heart of every action

Transparent & Trusted

clear cut processes trusted by 2000+ global sellers & brands

Amazon Seller Solutions Providers

servicing Amazon’s Global Sellers across Global Marketplaces